Cable Silicone Environmental Protection Is an Industry Trend

As environmental pollution worsens, people are increasingly paying attention to environmental protection, and the cable silicone industry is no exception. Environmental protection in the cable silicone industry mainly refers to material environmental protection.

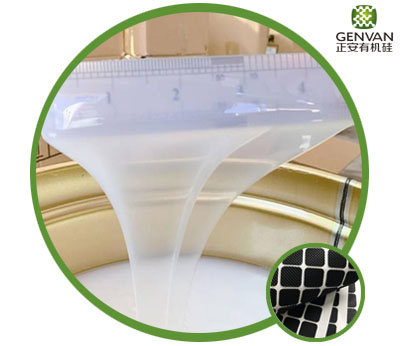

Most of the production of cable silicones use high molecular weight polymer blended chemical materials

Most of the production of cable silicones use high molecular weight polymer blended chemical materials such as silicone rubber, effectively reducing the production of toxic gases during the production process. Therefore, it is necessary to actively develop environmentally friendly materials and produce environmentally friendly cables. In recent years, the sales share of environmentally friendly cables has rapidly expanded, and ordinary cables and flame retardant cables can't compete with them. In addition, the waste produced during the cable production process can be directly recycled.

Cable silicone industry, also known as AGR silicone rubber cable, is made of silicone material, suitable for temperature range of -60℃ to 200℃, and can also be used in long-term humid environments with superior electrical and waterproof and anti-mildew properties. It has excellent bending performance, with a minimum bending radius of 16 times the cable diameter, and is portable. It is suitable for interconnecting mobile electrical equipment in high temperature environments such as power generation, metallurgy, and chemical industries. It is also suitable for wiring in high temperature places such as household appliances, lighting fixtures, electronic equipment, electric heating products, heavy machinery, power installations, industrial machines, electric heating products, and internal connection wires and instruments for microwave ovens, fax machines, printers, copiers, scanners, and electronic and gas appliances.

Different qualities of cable silicones have different prices

There are many types of cable silicones on the market, and different silicone materials, cable quality, and thickness will also have different prices. The difference in price mainly depends on the different quality of the cable itself. The insulating protective sheath made of different silicone quality will also have different effects, so the price difference of different quality cables is still quite large.

What we need to know is that the biggest feature of cable silicone is their high temperature resistance, corrosion resistance, and anti-aging properties. High-quality cables like high temperature cables can be used stably for more than 10,000 hours in a high-temperature environment of 200 degrees Celsius, and have high bending performance. They can be used in many harsh environments such as acidic, alkaline, and oily conditions. Therefore, the quality requirements are relatively high. Firstly, inferior cable silicones with cheap prices may have unclean rubber for making silicone, impurities and short vulcanization time of the rubber material. The screw for making silicone may not be smooth, resulting in phenomena such as sticking to the glue, so there may be some sulfurized rubber particles or impurities on the surface of the entire silicone protective sheath, and it won't feel smooth to the touch. The heat resistance may also be compromised.

Finally, the hole diameter of the entire mold sheath is relatively large, which causes a relatively large gap between the conductive conductor inside, the outer protective layer and the single wire layer, making the current transmission unstable and the cable outer layer appearing dents and other defects.

Popular Silicone Rubber Products

-

HTV Silicone Rubber

-

General HTV

- General Purpose Silicone Rubber For Molding (Precipitated/Fumed)

- High Strength Silicone Rubber

- Highly Anti-yellowing Silicone Rubber (Precipitated/Fumed)

- High Tear Strength Silicone Rubber for Molding (Precipitated/Fumed)

- High Resilience Fumed Silicone Rubber

- High-Transparent Fumed Silicone Rubber

- General Purpose Silicone Rubber For Extrusion (Precipitated/Fumed)

-

Advanced HTV

- High Hardness Silicone Rubber

- Low Hardness Silicone Rubber

- 2mm Flame Retardant Silicone Rubber

- High Strength Flame Retardant Silicone Rubber

- Flame Retardant Silicone Rubber (1mm: UL Yellow Card Cetificated)

- Silicone Rubber For Green Car

- Silicone Rubber for Cable Accessories (DBPMH/Platinum)

- Platinum Catalyzed Silicone Rubber For Extrusion

- Platinum Catalyzed Silicone Rubber For Molding

- Platinum Catalyzed Silicone Rubber for Medical Products

- Long Service Life Silicone Rubber for Buttons

- Antistatic Silicone Rubber (Precipitated/Fumed)

- Antistatic Silicone Rubber (Natural Color/Black)

- Oil-bleeding Silicone Rubber (Precipitated/Fumed)

- Thermally Conductive Silicone Rubber

- Oil Resistant Silicone Rubber

- Low Compression Set Silicone Rubber (Precipitated/Fumed)

- Heat Resistant Silicone Rubber (250 and 300 centigrade Degree)

- Hot Stamping Roll Silicone Rubber

- Heat Resistant and Flame Retardant Silicone Rubber

- Antibacterial silicone rubber (Precipitated/Fumed)

- GA-6071AHT series of Heat Cure Rubber (HCR)

-

General HTV

-

Liquid Silicone Rubber

- General LSR

-

Advanced LSR

- Non-post-curing Liquid Silicone Rubber

- Liquid Silicone Rubber For Cable Accessories

- Selective Self-Adhesive Liquid Silocone Rubber

- Low Viscosity Liquid Silicone Rubber

- Optical Liquid Silicone Rubber

- Self-Lubricating Liquid Silicone Rubber

- Liquid Silicone Rubber For Molding

- Liquid Silicone Rubber For Medical

- Liquid Silicone Rubber For Coating

- Antibacterial Liquid Silicone Rubber

- GA-23 Series Liquid Silicone Rubber

-

- What Is LSR?

-

Genvan liquid silicone rubber

Generate your Vantage - Home

- Company Profile

- FAQ

- HTV Silicone Rubber

- Clear Liquid Silicone Rubber

- Industrial

- General Purpose Silicone Rubber For Molding Fumed

- What Is HCR?

- “Scientific and technological innovation won the award again -- Genvan Silicone was recognized as "China's fluorine silicon industry innovative Enterprise"

- GENVAN Liquid silicone rubber factory

- Products

- Medical

- Document Download

- Liquid Silicone Rubber

- High Strength Liquid Silicone Rubber

- HTV Silicone Rubber

- General Purpose Silicone Rubber For Molding Precipitated

- Genvan Is One Of The Raw Material Manufacturers Of Bing Dwen Dwen

- Silicone Innovation

- Genvan product introduction - pad printing liquid silicone rubber

- About Us

- Automotive

- Blog

- General Purpose Liquid Silicone Rubber (Precipitated/Fumed)

- High Strength Silicone Rubber

- Liquid Silicone Rubber

- Wide Application Of Silicone Products In The Medical Industry

- Join with EP Power Show to create a new engine for the industry

- Applications

- Electronics

- Silicones Wiki

- Liquid Silicone Rubber For Baby Care

- High-Anti-Yellowing Silicone Rubber Fumed

- LSR Liquid Silicone Rubber

- Happy Women's Day

- Method For Improving Heat Resistance And Flame Retardancy Of Silicone Rubber

- Company News

- Resources

- Domestic Products

- Video

- General Purpose Silicone Rubber For Molding (Precipitated/Fumed)

- Non-post-curing Liquid Silicone Rubber

- High-Anti-Yellowing Silicone Rubber Precipitated

- LSR Liquid Silicone

- 8 Reasons Why Silicone Rubber is the Best Material for Medical Device Design

- Dongguan Genvan Silicone Technology Co., LTD., subsidiary of Genvan Group, wins the title of National SRDI "Little Giant" Enterprise!

- Contact Us

- Quality Control

- High Strength Silicone Rubber

- Liquid Silicone Rubber For Cable Accessories

- High Tear Strength Silicone Rubber for molding Fumed

- 2022, Genvan Will Build Dreams Of The Future!

- Silicone Rubber Company Video

- Composition of Silicone Rubber | Main Features and Uses of Silicone Rubber Products

- Search Result

- Highly Anti-yellowing Silicone Rubber (Precipitated/Fumed)

- Selective Self-Adhesive Liquid Silocone Rubber

- High Tear Strength Silicone Rubber for molding Precipitated

- Silicone Rubber Factory Video

- Processing Technology of Silicone Rubber

- Genvan Silicone attends the Honai International Maternity, Baby & Kids Fair

- Low Viscosity Liquid Silicone Rubber

- Search Result Products

- High Resilience Fumed Silicone Rubber

- Silicone Rubber Manufacturer Video

- Different Grades of Silicone Rubber Products | Why Do Many People Choose Medical Grade Silicone?

- Continuing to Expand Globally to Serve Clients and Planting the Seeds for Mutual Success in 2025

- High Tear Strength Silicone Rubber for Molding (Precipitated/Fumed)

- Optical Liquid Silicone Rubber

- Search Result Others

- High-Transparent Fumed Silicone Rubber Fumed

- Silicone Rubber Supplier Video

- How to Distinguish Ordinary Silicone and Platinum Silicone Products?

- Sitemap

- High Resilience Fumed Silicone Rubber

- Self-Lubricating Liquid Silicone Rubber

- General Purpose Silicone Rubber For Extrusion Fumed

- The Difference Between Food Grade and Medical Grade Silicone

- Genvan Silicone

- 404

- High-Transparent Fumed Silicone Rubber

- Liquid Silicone Rubber For Molding

- General Purpose Silicone Rubber For Extrusion Precipitated

- Safety Performance of Medical Silicone

- Privacy Policy

- General Purpose Silicone Rubber For Extrusion (Precipitated/Fumed)

- Liquid Silicone Rubber For Medical

- High Hardness Silicone Rubber

- What is Liquid Silicone?

- Submission Successful!

- High Hardness Silicone Rubber

- Liquid Silicone Rubber For Coating

- Low Hardness Silicone Rubber

- What Are the Main Factors That Affect the Surface Stickiness of Silicone Products?

- Taggg

- Low Hardness Silicone Rubber

- Antibacterial Liquid Silicone Rubber

- 2mm Flame Retardant Silicone Rubber

- Four Characteristics of High Temperature Cables

- GA-23 Series Liquid Silicone Rubber

- 2mm Flame Retardant Silicone Rubber

- High Strength Flame Retardant Silicone Rubber

- What Are the Applications and Functions of Silicone Rubber Products in the Automotive Industry?

- High Strength Flame Retardant Silicone Rubber

- Flame Retardant Silicone Rubber (1mm, UL Yellow Card Cetificated)

- Why Are Silicone Products So Popular?

- Flame Retardant Silicone Rubber (1mm: UL Yellow Card Cetificated)

- Silicone Rubber For Cable Accessories

- What Are the Differences between Liquid Silicone and Solid Silicone?

- Silicone Rubber For Green Car

- What Are the Definitions of Medical Silicone Materials?

- Silicone Rubber for Cable Accessories (DBPMH/Platinum)

- Platinum Catalyzed Silicone Rubber For Extrusion

- Application of Silicone Rubber Products in Various Industries

- Platinum Catalyzed Silicone Rubber For Extrusion

- Platinum Catalyzed Silicone Rubber For Molding

- Analysis of Reasons for Yellowing of Transparent Silicone Rubber

- Platinum Catalyzed Silicone Rubber For Molding

- Platinum Catalyzed Silicone Rubber For Medical

- What to Consider When Using Silicone Rubber in the Automotive Industry?

- Platinum Catalyzed Silicone Rubber for Medical Products

- Long Service Life Silicone Rubber for Buttons

- Application of Silicone Rubber Materials in Medical Devices

- Long Service Life Silicone Rubber for Buttons

- Ingredients and Characteristics of Medical Silicone

- Antistatic Silicone Rubber (Precipitated/Fumed)

- Application and Characteristics of Silicone Rubber

- Antistatic Silicone Rubber (Natural Color/Black)

- Antistatic Silicone Rubber Black

- Advantages of Liquid Rubber Compared to Solid Rubber

- Oil-bleeding Silicone Rubber (Precipitated/Fumed)

- What Are the Features of Cable Silicone?

- Thermally Conductive Silicone Rubber

- Oil-bleeding Silicone Rubber-Fumed

- Application of Typical Silicone Rubber Parts in Automobiles

- The Characteristics of Silicone Rubber and the Automotive Industry's Demands for It

- Oil Resistant Silicone Rubber

- Oil-bleeding Silicone Rubber-Precipitated

- What Are the Molding Processes of Liquid Silicone Rubber?

- Low Compression Set Silicone Rubber (Precipitated/Fumed)

- Thermal Conductivity Silicone Rubbers

- What Are the Requirements and Advantages of Medical-Grade Silicone Molding Technology?

- Heat Resistant Silicone Rubber (250 and 300 centigrade Degree)

- Oil Resistant Silicone Rubber

- What Is the Difference Between Medical-Grade Silicone Products and Regular Silicone?

- Hot Stamping Roll Silicone Rubber

- Oil-bleeding Silicone Rubber Fumed

- Why do Most Medical Silicone Products Use Liquid Silicone?

- Heat Resistant and Flame Retardant Silicone Rubber

- Oil-bleeding Silicone Rubber Precipitated

- Application of Silicone on Car Lights

- Antibacterial silicone rubber (Precipitated/Fumed)

- Low Compression Set Silicone Rubber Fumed

- The Difference Between Food-Grade Silicone and Regular Silicone

- GA-6071AHT series of Heat Cure Rubber (HCR)

- Low Compression Set Silicone Rubber Precipitated

- Production and Common Applications of Medical Silicone

- Heat Resistant Silicone Rubber (250 And 300 Centigrade Degree)GA-60X1A Series

- Reasons for the Reduction of Insulation Performance in Cable Silicone Rubber

- Heat Resistant Silicone Rubber (250 And 300 Centigrade Degree)GA-60X1F Seires

- Cable Silicone Environmental Protection Is an Industry Trend

- Hot Stamping Roll Silicone Rubber

- Does Higher Transparency of Medical Grade Silicone Tubing Indicate Better Quality?

- Heat Resistant And Flame Retardant Silicone Rubber

- Application of Silicone Rubber in New Energy Vehicles

- Antibacterial Silicone Rubber Fumed

- Why Is Medical Silicone Rubber Tubing Unique in the Field of Medicine?

- Antibacterial Silicone Rubber Precipitated

- Development Prospects of Medical Silicone

- An Introduction to the Medical Applications of Medical Silicone Hose

- How Much Do You Know About Medical Silicone Rubber Products?

- Design of Rubber Shock-Absorbing Components for Automobile Chassis

- Car Rubber Materials and Engine Suspension Damping System

- Application of Heat-resistant Silicone in Automotive Industry and Aerospace Field

- Performance Requirements of Car Silicone for Turbocharged Systems

- How Liquid Silicone Rubber Coating Can Improve Product Performance?

- What Is Oil Proof Rubber?

- The Benefits of Liquid Silicone Rubber Coating for Industrial Applications

- Applications of Oil Proof Rubber

- The Future of Liquid Silicone Rubber Coating: Innovations and Advancements

- How Heat-Conductive Silicone Rubber is Revolutionizing the Electronics Industry?

- Innovative Applications of Heat-Conductive Silicone Rubber for Thermal Management

- How to Choose the Right Flame Retardant Silicone Rubber for Your Project?

- The Science Behind Flame Retardant Silicone Rubber and How it Works

- The Benefits of Antimicrobial Silicone Rubber for Medical Devices

- How Does Platinum Catalyzed Silicone Rubber Compare to Other Types of Rubber?

- MSDS-General Purpose Silicone Rubber For Extrusion Fumed

- Common Uses of Platinum Catalyzed Silicone Rubber in Various Industries

- MSDS-General Purpose Silicone Rubber For Extrusion Precipitated

- Top 5 Uses of Heat Conductive Silicone Rubber in Industrial Applications

- MSDS-General Purpose Silicone Rubber For Molding Fumed

- Choosing the Right Heat Conductive Silicone Rubber: Factors to Consider

- MSDS-General Purpose Silicone Rubber For Molding Precipitated

- Exploring the Advantages of Heat Conductive Silicone Rubber in Electronic Devices

- MSDS-High Resilience Fumed Silicone Rubber

- Understanding the Curing Process of Platinum Catalyzed Silicone Rubber

- MSDS-High Strength Silicone Rubber

- The Ultimate Guide to Platinum Catalyzed Silicone Rubber: Properties and Applications

- MSDS-High Tear Strength Silicone Rubber for Molding Fumed

- Heat Conductive Silicone Rubber vs. Traditional Thermal Interface Materials: A Comparative Analysis

- MSDS-High Tear Strength Silicone Rubber for Molding Precipitated

- What is Medical Grade Liquid Silicone and Its Applications in Healthcare?

- MSDS-High-Anti-Yellowing Silicone Rubber Fumed

- Is Medical Grade Liquid Silicone Safe for Use in Implants?

- MSDS-High-Anti-Yellowing Silicone Rubber Precipitated

- The Role of Medical Grade Liquid Silicone in Medical Wearables

- MSDS-High-Transparent Fumed Silicone Rubber Fumed

- What is Fuel Proof Rubber and Why is it Important in Automotive Applications?

- MSDS-2mm Flame Retardant Silicone Rubber

- Effect of Curative Systems on the Properties of High Temperature Resistant Silicone Rubber

- MSDS-Antibacterial Silicone Rubber-Fumed

- Manufacturing Technologies for High Temperature Resistant Silicone Rubber

- MSDS-Antistatic Silicone Rubber Black

- Design and Optimization of Petrol Resistant Rubber Products for Automotive and Industrial Applications

- MSDS-Antistatic Silicone Rubber Fumed

- Multi-Functional Properties of High Tear Strength Silicones

- MSDS-Antistatic Silicone Rubber Natural Color

- Applications of High Tear Strength Silicones in Medical and Healthcare Industries

- MSDS-Antistatic Silicone Rubber Precipitated

- Properties and Applications of Petrol Resistant Rubber

- Future Directions and Challenges in Low Viscosity Silicone Rubber Research and Development

- MSDS-Flame Retardant Silicone Rubber (1mm, UL Yellow Card Cetificated)

- Low Viscosity Silicone Rubber for High-Performance Coatings and Adhesives

- MSDS-Heat Resistant and Flame Retardant Silicone Rubber

- Quality Control and Assurance in Silicone Rubber Baby Mold Production

- MSDS-Heat Resistant Silicone Rubber (250 and 300 Centigrade Degree)

- Design Considerations for Silicone Rubber Baby Molds

- MSDS-High Hardness Silicone Rubber

- Processing and Manufacturing Techniques for Optically Clear Liquid Silicone Rubber

- MSDS-High Strength Flame Retardant Silicone Rubber

- Optical Properties of Optically Clear Liquid Silicone Rubber

- MSDS-Hot Stamping Roll Silicone Rubber

- The Heat Resistance of Silicone Rubber

- MSDS-Long Service Life Silicone Rubber for Buttons

- Unleashing the Power of Fuel-Proof Silicone: Protecting Your Equipment and Components

- MSDS-Low Compression Set Silicone Rubber Fumed

- Step-by-Step: How to Apply Silicone to Your Car Windshield for a Perfect Seal

- MSDS-Low Compression Set Silicone Rubber Precipitated

- Why Silicone is the Perfect Sealant for Your Car Windshield?

- MSDS-Low Hardness Silicone Rubber

- Choosing the Right Silicone for Your Car Windshield: Factors to Consider

- MSDS-Oil Resistant Silicone Rubber

- Fuel-Proof Silicone: Versatile Applications for Ultimate Protection

- MSDS-Oil-Bleeding Silicone Rubber Fumed

- How to Choose the Right Fuel-Proof Silicone for Your Needs?

- MSDS-Oil-Bleeding Silicone Rubber Precipitated

- Silicone Flame Retardant: Understanding its Importance and Applications

- MSDS-Platinum Catalyzed Silicone Rubber For Extrusion

- How to Test and Certify the Effectiveness of Silicone Flame Retardant?

- MSDS-Platinum Catalyzed Silicone Rubber For Medical

- Common Uses of Silicone Flame Retardant in Electrical and Electronic Industries

- MSDS-Platinum Catalyzed Silicone Rubber For Molding

- MSDS-Silicone Rubber for Cable Accessories Platinum

- MSDS-Silicone Rubber for Cable Accessories-DBPMH

- MSDS-Silicone Rubber For Green Car

- MSDS-Thermal Conductivity Silicone Rubber

- MSDS-General Purpose Liquid Silicone Rubber Fumed

- MSDS-General Purpose Liquid Silicone Rubber Precipitated

- MSDS-Clear Liquid Silicone Rubber

- MSDS-High Strength Liquid Silicone Rubber

- MSDS-Liquid Silicone Rubber For Baby Care

- MSDS-Addition Cure Liquid Silicone Rubber For Molding

- MSDS-Antibacterial Luquid Silicone Rubber

- MSDS-Liquid Silicone Rubber For Cable Accessories

- MSDS-Liquid Silicone Rubber For Coating

- MSDS-Liquid Silicone Rubber For Medical

- MSDS-Low Viscosity Liquid Silicone Rubber

- MSDS-Non-post Cure Liquid Silicone Rubber

- MSDS-Optical Liquid Silicone Rubber

- MSDS-Selective Self-Adhesive Liquid Silocone Rubber

- MSDS-Self-Lubricating Liquid Silicone Rubber

- MSDS-General Purpose Silicone Rubber For Molding Precipitated

- MSDS-antibacterial Silicone Rubber

中文

中文